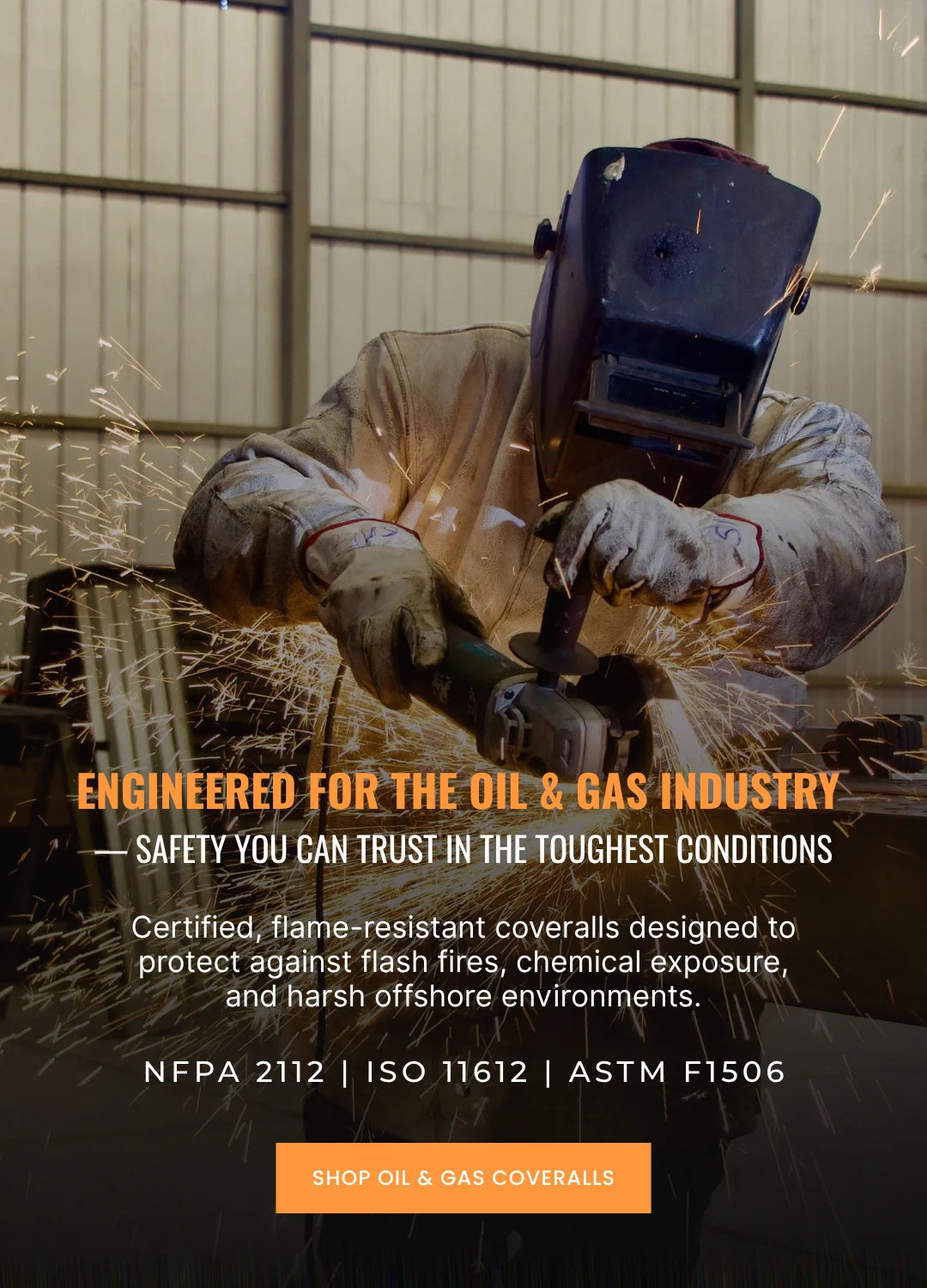

In the oil and gas industry, workers are exposed to high-risk environments where a small spark or chemical spill can cause severe damage. Standard uniforms fail to provide enough safety in such conditions. That’s where RigArmor’s fire retardant oil and gas workwear makes all the difference, providing enough protection, durability, and comfort for field operations.

✓ Flash fire & arc flash protection

✓ Chemical splash resistance

✓ High-visibility in low-light zones

✓ Durable for offshore and refinery use

Fire Retardant Protection You Can Rely On

RigArmor’s oil and gas coveralls are built from flame-resistant (FR) fabrics that meet globally recognized safety standards. These fabrics are designed to self-extinguish once the source of ignition is removed, minimizing burn injuries and giving workers crucial seconds to react.

✓ NFPA 2112 Certified: Offers tested protection against flash fires.

✓ ISO 11612 Certified: Guards against heat and flame exposure.

✓ ASTM F1506 Compliant: Provides arc flash resistance in electrical risk zones.

✓ OSHA Approved: Meets workplace safety requirements for industrial workwear.

This multilayered compliance ensures that every RigArmor garment offers peace of mind in high-risk environments both onshore and offshore.

The Realities of Oilfield Work

Workers involved in the oil and gas industries work under extreme heat, flash fires, and chemicals. Standard uniforms can ignite, melt, or tear under such conditions, putting lives at risk.

RigArmor’s industrial coveralls for oil and gas workers are engineered to withstand the toughest job sites. Every product is tested and certified to international safety standards. It ensures workers remain protected while maintaining mobility and comfort throughout long shifts.

Engineered for Comfort and Longevity

Built for the Demands of the Oilfield

-

Flame-Resistant Fabrics

Certified protection against flash fires -

Durable Stitching

Withstands tough environments -

Comfortable Fit

Breathable industry workwear for long shifts -

Custom Embroidery

Branding and identification made easy -

Industry Certifications

NFPA 2112, ISO 11612, ASTM F1506

Built for the Demands of the Oilfield

RigArmor understands the physical and environmental challenges oilfield workers face daily. Each element of its fire retardant workwear is engineered for endurance, safety, and practicality.

Flame-Resistant Fabrics

Certified protection against flash fires, offering advanced thermal insulation while maintaining breathability.

Durable Stitching

Heavy-duty construction that resists tearing, fraying, and wear, even in the harshest conditions.

Comfortable Fit

Breathable materials and ergonomic design ensure all-day comfort during long shifts in the field.

High-Visibility Safety

Reflective trims enhance visibility in low-light zones, improving safety during night operations.

Custom Embroidery

Personalized branding and team identification can be added without compromising the integrity of the fabric flame resistance.

Industry Certifications

Each garment carries global certifications such as NFPA 2112, ISO 11612, and ASTM F1506, ensuring total compliance and trust.

Certified to Global Safety Standards

Every RigArmor product is crafted to meet international safety standards. These certifications represent a commitment to worker safety and corporate responsibility.

✓ NFPA 2112: Certified flame-resistant coveralls for flash fire protection.

✓ ISO 11612: Protective clothing against heat and flames.

✓ ASTM F1506: Flame-resistant materials for arc flash protection.

✓ OSHA Compliant: Fully approved for workplace safety compliance.

With this level of certification, RigArmor’s oil and gas coveralls provide reliable protection for high-demand industries where failure isn’t an option.

Engineered for Comfort and Longevity

Chemical & Environmental Resistance

Oil and gas environments are exposed to various chemicals and corrosive elements. RigArmor’s oil and gas workwear integrates chemical splash resistance to safeguard workers from potential hazards. The materials repel harmful substances and maintain protective performance even after multiple industrial washes.

Engineered for Comfort and Longevity

- RigArmor’s design blends protection with practicality, ensuring that every piece of gear enhances mobility and reduces fatigue. Elastic waistbands, reinforced seams, and breathable panels make these industrial coveralls for oil and gas workers ideal for extended use in both hot and humid conditions.

- Unlike standard uniforms that lose strength or protection after repeated washing, RigArmor’s fire retardant technology makes the uniforms durable and long-lasting.

Designed for Every Oil & Gas Operation

Offshore Drilling Platforms

Resistant to sea spray, wind, and flame hazards

Refineries & Processing Plants

Meets compliance for chemical and heat protection

Maintenance & Pipeline Operations

Enhanced mobility and reflective visibility

Choose RigArmor – Trusted by Industrial Professionals

When it comes to oil and gas workwear, RigArmor stands as a trusted name across offshore rigs, refineries, and chemical plants. Every garment combines innovation, safety, and comfort, ensuring your crew is always protected and performing at their best.

Protect your team with certified performance.

View RigArmor’s Fire Retardant Coveralls

Engineered for Comfort and Longevity

Frequently Asked Questions

Are your coveralls certified for oil and gas industry standards?

Are your coveralls certified for oil and gas industry standards?

Yes. All our Oil & Gas coveralls are certified to NFPA 2112, ISO 11612, and ASTM F1506 standards, ensuring protection against flash fires, heat, and flame exposure. Each garment undergoes rigorous testing to meet OSHA and global safety requirements.

Can I customize the coveralls with my company logo or specific colors?

Can I customize the coveralls with my company logo or specific colors?

Absolutely. We offer custom embroidery, color options, and made-to-order sizing to match your company’s branding and safety requirements. Simply submit your logo and specifications, and our production team will handle the rest.

Do you supply coveralls for offshore and refinery environments?

Do you supply coveralls for offshore and refinery environments?

Yes. Our coveralls are specifically designed for offshore drilling platforms, refineries, and onshore operations. They offer flame resistance, chemical splash protection, and high visibility—ideal for harsh, high-risk conditions.

What’s the typical lead time for bulk or custom orders?

What’s the typical lead time for bulk or custom orders?

Standard orders are shipped within 5–7 business days, while customized or bulk orders typically take 2–3 weeks, depending on order size and requirements. Rush orders can be accommodated on request.

How do I choose the right size and fit for my team?

How do I choose the right size and fit for my team?

Each product page includes a detailed size chart with measurement guides for accurate fit. For large teams, we also offer consultation support to ensure every employee receives the correct size and comfort level.

Are your coveralls certified for oil and gas industry standards?

Are your coveralls certified for oil and gas industry standards?

Can I customize the coveralls with my company logo or specific colors?

Can I customize the coveralls with my company logo or specific colors?

Do you supply coveralls for offshore and refinery environments?

Do you supply coveralls for offshore and refinery environments?

What’s the typical lead time for bulk or custom orders?

What’s the typical lead time for bulk or custom orders?

How do I choose the right size and fit for my team?

How do I choose the right size and fit for my team?